The Future of Manufacturing: Rapid 3D Prototyping for Metal Fabricators

In the rapidly evolving world of manufacturing, businesses are constantly seeking innovative solutions to stay competitive. One of the most transformative technologies in recent years is rapid 3D prototyping. This cutting-edge technique plays a crucial role in metal fabrication, allowing businesses to streamline their production processes, reduce costs, and improve product quality. In this article, we will explore the ins and outs of rapid 3D prototyping, its applications in the metal fabrication industry, and how it can elevate your business.

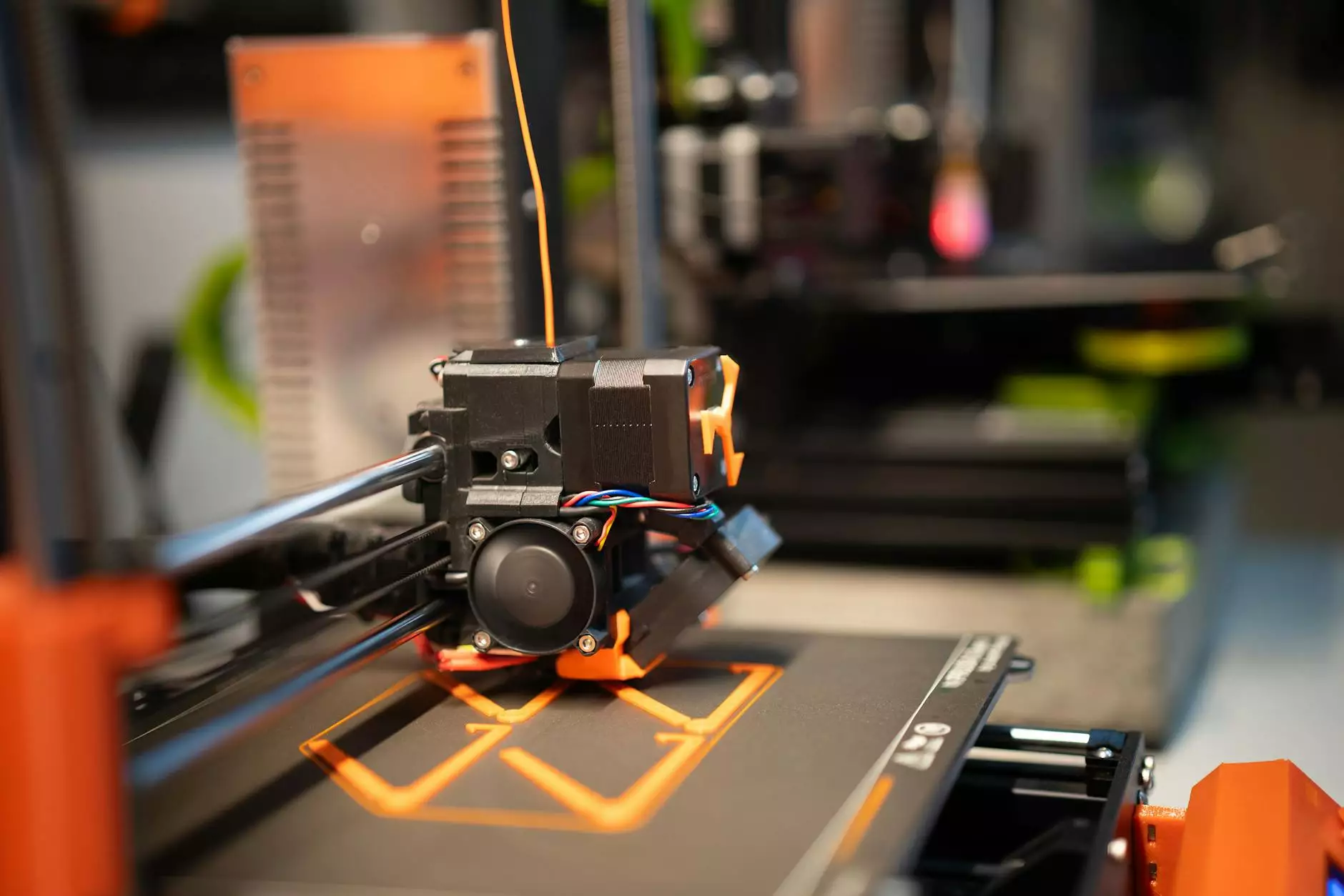

Understanding Rapid 3D Prototyping

Rapid 3D prototyping refers to the process of quickly creating a scale model of a physical part or assembly using 3D computer-aided design (CAD) data. This technique allows designers and engineers to visualize their concepts before committing to full-scale production, thus enabling them to identify any potential issues early in the design phase. By utilizing additive manufacturing technologies, such as 3D printing, businesses can produce prototypes with intricate designs and geometries that may be impossible to achieve with traditional manufacturing methods.

Key Benefits of Rapid 3D Prototyping

Implementing rapid 3D prototyping in your metal fabrication processes offers numerous advantages, which include:

- Reduced Time to Market: One of the primary benefits of rapid prototyping is the significant reduction in the time required to develop and test prototypes. This acceleration allows businesses to bring their products to market faster than ever before.

- Cost-Effectiveness: By minimizing the resources needed for traditional prototyping, such as tooling and material costs, companies save money while still producing high-quality prototypes.

- Enhanced Design Flexibility: Rapid prototyping allows engineers to experiment with various designs and make adjustments in real-time, leading to better end products.

- Improved Product Quality: By identifying design flaws early in the development phase, companies can make necessary adjustments, resulting in higher-quality final products.

- Increased Collaboration: 3D prototypes facilitate better communication among team members, stakeholders, and clients, as they can view and interact with tangible models of the products.

Applications of Rapid 3D Prototyping in Metal Fabrication

The metal fabrication industry can greatly benefit from the integration of rapid 3D prototyping. Some key applications include:

1. Custom Tooling

Metal fabrication often requires specialized tools and fixtures. With rapid prototyping, businesses can create custom tooling quickly and cost-effectively, ensuring precision and efficiency in production.

2. Prototype Parts

When developing new metal products, quick iterations are crucial. Rapid prototyping enables fabricators to create functional prototypes that closely mimic the final product, reducing the risk of errors during the production phase.

3. Testing and Validation

Before moving to full-scale production, it's essential to test product designs. Rapid prototypes can be used for functional testing, ergonomic assessments, and design validation.

4. Small Batch Production

For companies that require limited production runs, rapid 3D prototyping allows for cost-effective creation of small batches without the need for expensive tooling investments.

Technologies Behind Rapid 3D Prototyping

Several key technologies drive the rapid 3D prototyping process, including:

- Fused Deposition Modeling (FDM): This method involves the extrusion of thermoplastic filament through a heated nozzle, layer by layer, to build the prototype.

- Stereolithography (SLA): SLA uses ultraviolet light to cure liquid resin into hardened plastic, allowing for fine details and smooth surfaces.

- Selective Laser Sintering (SLS): SLS utilizes a high-powered laser to fuse powdered materials, such as metals and plastics, into solid structures.

- Direct Metal Laser Sintering (DMLS): This is a specialized form of SLS that specifically addresses metal parts, allowing for complex geometries and high-strength components.

Integrating Rapid 3D Prototyping into Your Business

Adopting rapid 3D prototyping into your metal fabrication processes requires careful planning and execution. Here are some key steps to consider:

1. Assess Your Needs

Understanding the specific needs of your business is essential. Evaluate the types of products you manufacture, the complexity of designs, and the volume of production required.

2. Choose the Right Technology

Based on your needs, select the rapid prototyping technology that best aligns with your manufacturing requirements. Consider factors such as material compatibility, production speed, and cost.

3. Collaborate with Experts

Partnering with experienced professionals who specialize in rapid prototyping can provide valuable insights and guidance throughout the integration process.

4. Train Your Team

Ensure that your team is equipped with the knowledge and skills necessary to operate and maintain the rapid prototyping equipment effectively.

5. Monitor and Optimize

After implementation, continually assess the performance of your rapid prototyping processes to identify areas for improvement and optimization.

Challenges and Considerations

While rapid 3D prototyping presents numerous benefits, it's essential to recognize potential challenges as well:

- Material Limitations: Not all materials are suitable for rapid prototyping, which may limit design choices.

- Initial Costs: The investment in rapid prototyping technology can be high, though it typically pays off over time.

- Technical Expertise: A lack of skilled personnel can hinder the successful implementation of new technologies.

The Future of Rapid 3D Prototyping in Metal Fabrication

The future of rapid 3D prototyping in metal fabrication is bright, poised to revolutionize how products are designed, developed, and manufactured. As technology continues to advance, we can expect:

- Increased Adoption: More businesses will leverage rapid prototyping to improve efficiency and reduce costs.

- Innovative Materials: The development of new materials for 3D printing will broaden the possibilities for prototyping and production.

- Improved Automation: Increased automation in the prototyping processes will enhance production speed and consistency.

Conclusion

In conclusion, rapid 3D prototyping is not just a passing trend; it is a fundamental shift in how the metal fabrication industry operates. By embracing this innovative technology, businesses can achieve significant advantages in speed, flexibility, and quality, positioning themselves to thrive in a competitive landscape. Investing in rapid prototyping could be the key to unlocking new opportunities and driving growth within your organization.

At DeepMould, we understand the vital role of cutting-edge technologies in metal fabrication. Our commitment to excellence and innovation helps businesses leverage the power of rapid 3D prototyping to transform their manufacturing processes and achieve remarkable results.